HOLLOWING TOOLS

HOLLOWING WITH WOODCUT TOOLS

"Make shavings, not dust"

Ken Port (Woodcut founder) demonstrated woodturning at the 1979 Nambassa Music festival in Waikato New Zealand, it was here that Ken met Paul Beckett who also had a passion in turning. Paul hollowed with an evolution of the traditional hook cutter with a shield to prevent dig ins. The shape of Paul’s cutter was inspired by the unique curved shape of french tapestry.

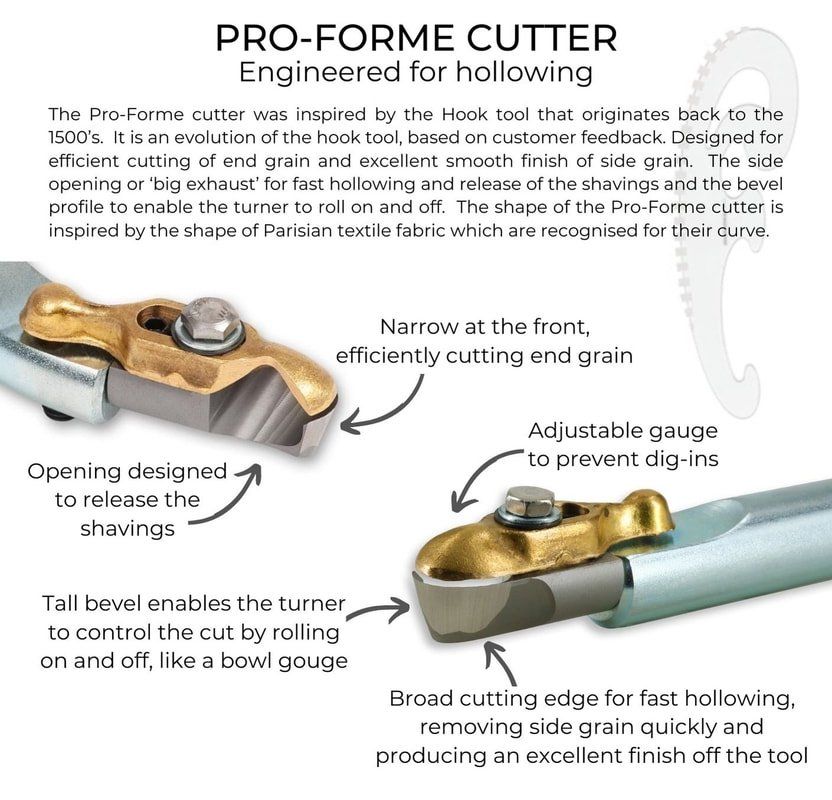

The narrow nose of the M2 high speed steel cutter is uniquely designed for efficient cutting of end grain and excellent smooth finish of side grain. The side opening or ‘big exhaust’ for fast hollowing and release of the shavings and the tall bevel profile to enable the turner to roll on and off.

Ken and the Hewitt family have listened to customers and steadily improve over time the Woodcut Tool’s range of hollowing products. A handle that can be simply extended to provide additional leverage, especially for larger projects. A collaboration with UK professional turner led to the Woodcut Irons Tool Gate and the Irons Shear Scraper, based on the idea of a cabinet maker’s scraper to refine and smooth off the tool the outside of hollow forms.

Making it as easy as possible for customers to enjoy the experience, by taking the tool, put to wood and see the shavings!

Pro-Forme Hollowing

USER GUIDES - PDFS

Click below to download the user guides on our Pro-Forme hollowing tools.